Tuesday, September 30, 2014

The Beauty of Koa

I got some decent Koa and went to town on a Foti-style steering blade. I've cracked the code on getting a nice gloss on epoxy (it's no secret...let it cure and sand progressively up to 2500 grit, then rubbing compound, then polishing glaze).

Friday, July 4, 2014

Palaoa #3: North Cackalackee

Sunday, June 1, 2014

The "Kona"

This design pretty much contains all of that. Inspired by Dan Thomson's designs (particularly the Vanguard), I built up a template that was the next logical step coming from the Palaoa quad, which I've been riding nearly exclusively since I built it. The Palaoa rips, but because of the extremely low tail rocker it is a bit more stiff than I like. While adding tail rocker will increase maneuverability, it also slows it down, so it's a balance that must be struck carefully.

This one is 5'8" x 19" (contrast with the Palaoa's 5'10"x 22" outline). I started with a single concave nose to tail. At the tail, outside of the concave I carved in some vee and concaved those veed-out areas. Inside the concave I did four channels...so there is vee, concave, and channels all working to keep the tail loose while channeling speed. I added a 5th fin box to make it either a quad, thruster or knubster (quad with a mini 5th fin), as there were days when I wanted the drive of a thruster out of my Palaoa.

I could have went with a traditional rounded nose, but seeing Stu Kennedy ripping on one of Tomo's Vanguards made me cut it into that unusual diamond outline (as with the tail)...yes, I'm treading on ripping off Tomo, but I built it for my own fun this summer, so please Tomo don't sue me.

And the color...full resin tint top and bottom with cutlap and pinlines. Definetely a challenge. A bit more trippendicular than intended but once I started, I just couldn't stop.

Saturday, May 3, 2014

What Goes Into a Paddle

All of my paddles, whether functional or decorative, are made the same way.

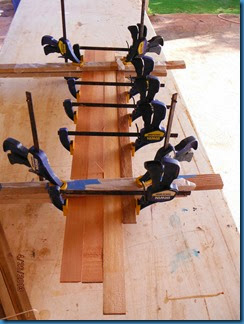

I mill my stock from a variety of woods, typically mahogany, fir, redwood and cedar:

Those are glued and clamped to create the blank for the paddle shaft. In the case of single or double bend shafts, I have jigs that I clamp them to achieve the bend.

Here is a double-bend SUP paddle coming out of the jig:

From there, I square out the blank with a planer, and then develop the oval shape of it using hand planes:

The blade is made of similar tight-grained, book-matched wood, edge-glued and clamped, with a temporary jig to keep things aligned. Here instead of book-matching I made one long blade that will get halved for gluing on to the shaft:

Another temporary jig to attach the blade halves to the shaft. I’ll use 4 or more big clamps normally; this shows the first two:

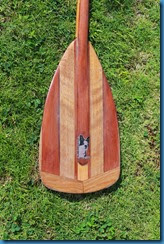

From there I use one of my paddle templates to draw the blade shape, and cut it with a jigsaw. From there it’s down to final shaping and sanding. I usually add a piece of hardwood at the bottom of the blade running perpendicular (or at an acute angle) to the rest of the grain – this not only looks good but makes the blade structurally stronger:

From there, the blades get a layer of fiberglass set in epoxy. The whole paddle is coated in epoxy, sanded and recoated until glassy smooth. I wood-burn the serial number and my signature, set any graphics under the glass, and voila! Beautiful and functional.

Thursday, February 20, 2014

200 Videos

My Vimeo account has reached 200 videos. While I know that’s a bit like saying “AC/DC made 15 Albums” when really they made essentially the same album 15 times, it’s significant nonetheless.

As such, here is number 200. Hope you’ve got 20 minutes to kill.